How Mobile Hose Repair Keeps High-Demand Sites Moving

Hydraulic systems sit at the heart of manufacturing, construction, transport, waste, plant, and utilities. When a hose fails, everything stops. High-demand sites can’t afford long delays or downtime, which is why mobile hydraulic hose repair has become a critical support service.

This article explains how onsite repair keeps operations running, cuts risk, and protects productivity across Northern Ireland’s busiest industrial environments.

Why Hydraulic Hose Reliability Matters

In fast-paced industrial settings, a single hydraulic fault can halt production, compromise safety, and trigger costly knock-on delays. High-demand sites rely on equipment running continuously, so hose reliability isn’t just a maintenance concern, it’s integral to operational stability.

Understanding the pressures and failure risks helps engineers spot issues early and avoid unplanned stoppages.

Common Failure Points Engineers See on Busy Sites

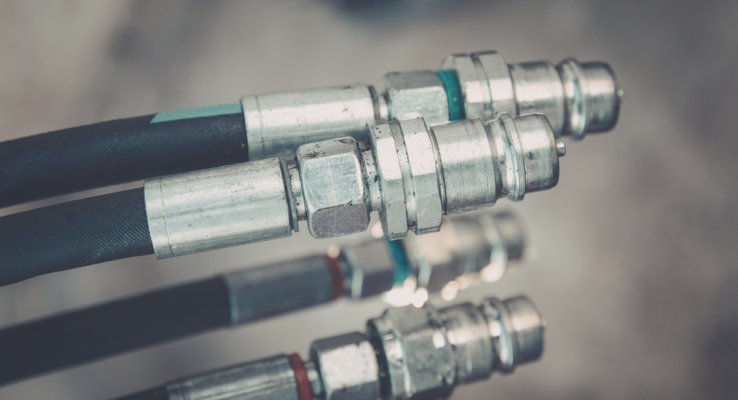

Heavy abrasion, intense pressure cycles, and exposure to oils, heat, and vibration combine to create predictable failure points. Engineers often encounter cracked outer covers, damaged fittings, and pinhole leaks that escalate rapidly under load.

Safety, Productivity, and Compliance: The Hidden Risks of Delays

Beyond downtime, hose failures risk hydraulic injection injuries, environmental spills, and breaches of safety protocols. Delayed responses can also push sites out of compliance with LOLER, PUWER, and other regulatory requirements tied to equipment performance.

What Mobile Hydraulic Hose Repair Actually Involves

Mobile repair isn’t just a “call-out”. It’s a structured, engineered process designed to get machinery back online safely and quickly. The real advantage comes from having trained hydraulic specialists arrive with the tools, diagnostic equipment, and stock needed to rebuild hoses on the spot.

Rapid Onsite Response and Diagnostics

Engineers assess the failure area, identify the root cause, and confirm any secondary risks before starting work. This ensures the fix addresses the underlying issue, not just the visible fault.

Building and Fitting Replacement Hoses at the Point of Failure

Each hose is cut, assembled, and crimped to specification onsite. This guarantees the correct length, routing, and pressure rating without transporting machinery to a workshop.

Pressure Testing and Quality Checks Before Restarting Operations

Before machinery resumes work, engineers carry out controlled pressure checks to confirm safety and performance. This prevents repeat failures and reduces the risk of immediate rework.

How Fully Equipped Service Vans Speed Up the Process

Stocked with fittings, adaptors, hose types, and crimping gear, service vans function as mobile workshops. This enables a first-time fix on most call-outs and removes the delays caused by sourcing parts offsite.

When to Call a Mobile Hose Repair Specialist

Knowing when to call for support prevents small issues from becoming major failures. High-demand sites gain the most value when they act before performance drops significantly.

Early Warning Signs Engineers Should Never Ignore

Slow movements, visible abrasion, minor drips, and changes in pressure response indicate developing problems.

Situations Where Immediate Onsite Response Prevents Escalation

Burst hoses, loss of pressure, and equipment immobilisation require urgent specialist support to avoid further damage.

Why 24/7 Availability Matters for Heavy-Use Sites

Many industrial operations run around the clock. Having access to engineers at any hour ensures faults are resolved without waiting for the next working day.

How Hydraquip Keeps Industrial and Manufacturing Sites Moving

Hydraquip supports high-demand sectors by combining rapid response, industry expertise, and fully equipped vans. The service is engineered to minimise downtime and deliver safe, compliant repairs at any time of day.

Round-the-clock availability ensures critical faults are dealt with immediately.

Engineers understand the operational pressures faced in construction, manufacturing, utilities, transport, and more.

Carrying a full range of hoses, fittings, and tools allows most repairs to be completed within a single visit.

Hydraquip has extensive experience working with sites that can’t afford downtime, delivering dependable results across Northern Ireland.

Conclusion

Mobile hydraulic hose repair plays a vital role in keeping high-demand sites operational. By delivering engineered solutions directly to the point of failure, companies avoid costly delays, reduce risk, and maintain productivity.

Hydraquip’s 24/7 mobile service ensures industrial and manufacturing sites across Northern Ireland stay moving when it matters most.