Reliable Hose Repairs for Waste Management & Recycling

Waste management and recycling operations rely heavily on machinery that simply cannot afford to stop. From collection fleets to sorting plants, every piece of equipment is under constant pressure to perform. When a hydraulic hose fails, the result is downtime, missed schedules, and mounting costs. Reliable hose repairs are therefore not just a maintenance concern, they are a business-critical service that keeps waste and recycling moving without disruption.

This article explores the role of dependable hose repairs in waste management and recycling, the risks of failure, and the value of having rapid onsite support when it matters most.

The Demands of Waste Management & Recycling Operations

The waste management and recycling sector operates under some of the toughest conditions in industry. Equipment is constantly in use, often in dirty, abrasive, and high-pressure environments. Hydraulic systems power everything from collection lorries to compactors and sorting machinery, meaning that hose reliability is vital for keeping operations running smoothly. Any unplanned stoppage has a direct impact on productivity, costs, and service delivery.

Hydraulic Systems at the Core of Heavy-Duty Equipment

Hydraulics drive the essential functions of waste and recycling equipment, including compaction, lifting, crushing, and sorting. Without robust hydraulic performance, vehicles and plant simply cannot operate.

Continuous Pressure on Fleets and Plant Equipment

Waste handling equipment works long shifts with little downtime. The constant strain of heavy loads, tight schedules, and demanding environments means hoses are more prone to wear and damage compared with many other industries.

The Cost of Downtime in the Waste & Recycling Sector

When a vehicle or plant system is taken out of service due to a hose failure, the disruption is immediate. Collection routes are delayed, recycling targets are missed, and costs escalate through both idle labour and emergency call-outs.

Why Hydraulic Hose Reliability Matters

In waste management and recycling, equipment reliability underpins both safety and commercial performance. Hydraulic hoses are often pushed to their limits, and when they fail, the consequences are far-reaching. By focusing on hose reliability, operators can protect workers, maintain service levels, and reduce unnecessary costs.

Safety Concerns Linked to Hose Failure

A burst or leaking hose poses an immediate safety risk. High-pressure fluid can cause serious injury to operators and maintenance staff, while leaks increase the risk of slips, environmental hazards, and fire.

Protecting Productivity and Service Contracts

Most waste management providers operate under strict collection timetables and service-level agreements. Hose failure that halts a vehicle or plant line can quickly result in penalties, reputational damage, and unhappy clients.

Reducing Costs with Preventive Maintenance

Investing in regular hose inspections and timely replacement reduces the likelihood of catastrophic failures. This not only cuts unplanned downtime but also keeps maintenance budgets under control by avoiding larger, reactive repair costs.

Common Hose Issues in Waste Management & Recycling

The harsh operating environments of waste management and recycling put hydraulic hoses under extreme strain. Heavy workloads, constant movement, and exposure to challenging conditions all contribute to premature wear and unexpected failures. Understanding the most common issues helps operators plan better maintenance and minimise costly breakdowns.

Wear from Abrasive Materials and Heavy Loads

Compactors, balers, and refuse collection vehicles handle tonnes of abrasive waste every day. The vibrations, impacts, and weight place hoses under constant stress, leading to accelerated wear and reduced service life.

Damage from Harsh Weather and Environmental Conditions

Waste operations don’t stop for bad weather. Hoses are exposed to rain, frost, heat, and contaminants such as oil, chemicals, and grit. Over time, this exposure weakens hose integrity and increases the chance of leaks or bursts.

Failures from High-Pressure Cycles and Heavy Usage

Hydraulic systems in recycling and waste handling equipment regularly run at high pressure. Constant cycling combined with extended use can cause fatigue, internal damage, and eventual hose failure if not addressed.

The Solution – Reliable Mobile Hose Repairs from Hydraquip

When hydraulic hoses fail, the ability to get equipment back in service quickly is critical. Mobile hose repair services provide the fastest and most effective solution, bringing expertise and equipment directly to the site. This eliminates the need to transport vehicles or machinery offsite, cutting downtime and restoring productivity without unnecessary delays.

24/7 Call-Outs to Minimise Downtime

With waste and recycling fleets often operating round the clock, hose failures can occur at any time. A 24/7 call-out service ensures operators aren’t left waiting until the next working day, keeping disruption to a minimum.

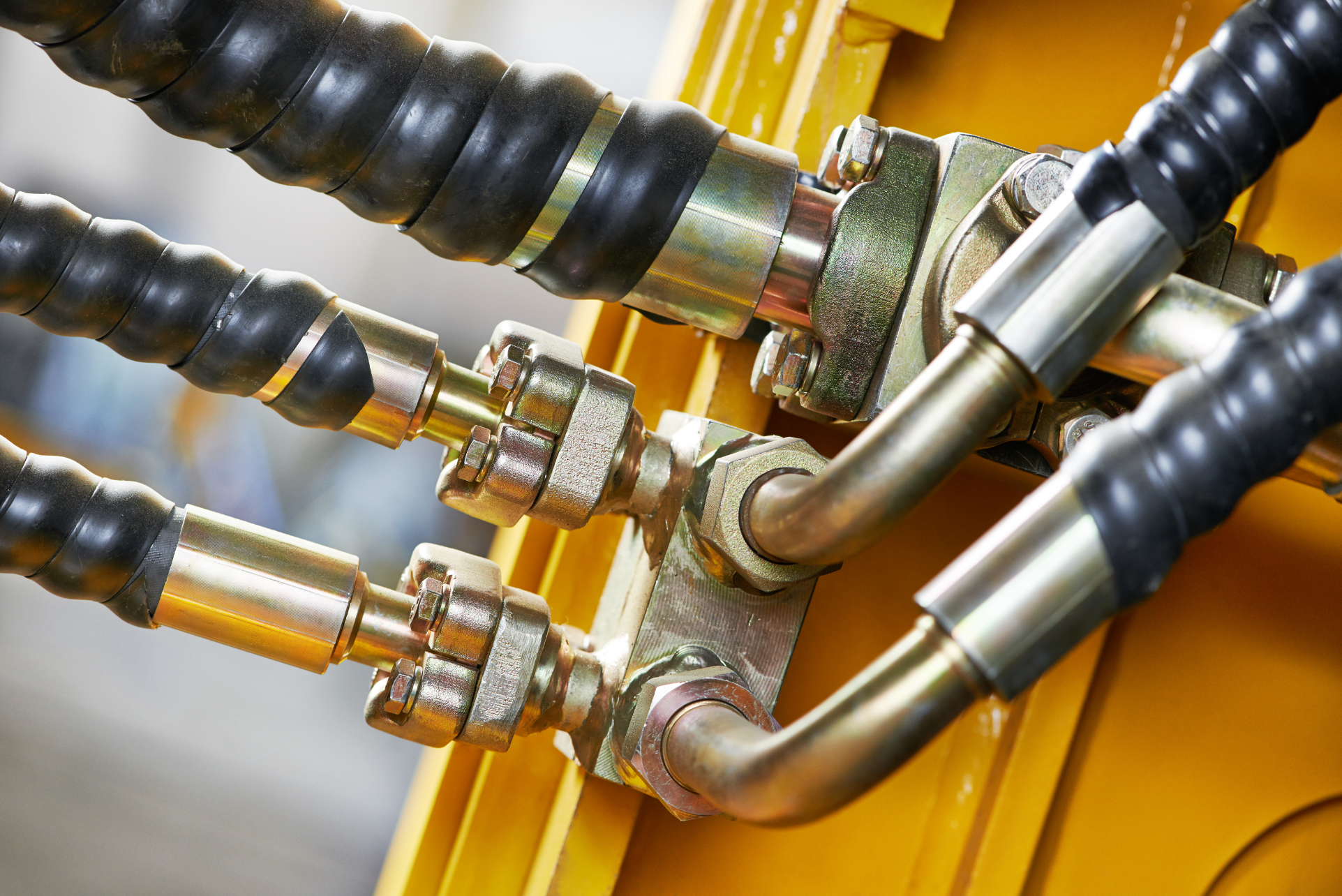

Fully Equipped Vans for Onsite Repairs

Mobile service units carry a full stock of hose, fittings, and tools. Engineers can cut, assemble, and fit replacements immediately, providing a first-time fix that gets machinery back in action without repeat visits.

Skilled Engineers with Industry-Specific Knowledge

Repairing hoses in waste and recycling applications requires more than general hydraulic expertise. Engineers with knowledge of the sector understand the unique pressures on equipment and can recommend durable solutions that stand up to demanding use.

First-Time Fix Rates and Rapid Response

The combination of round-the-clock availability, fully stocked vans, and experienced engineers delivers high first-time fix rates. A rapid response directly translates into reduced downtime and lower operational costs.

Why Use Hydraquip for Your Hose Repairs

Choosing the right repair partner is critical for waste management and recycling businesses. Hydraquip provides a complete service that combines technical expertise, rapid response, and sector-specific knowledge, ensuring your operations remain reliable and cost-effective.

Proven Expertise in Waste & Recycling

Our engineers are highly trained and experienced in supporting waste management fleets and recycling facilities. This industry knowledge ensures effective, durable repairs every time.

Fast Response and Transparent Service

With 24/7 coverage and rapid dispatch, Hydraquip minimises downtime when it matters most. Clear communication and straightforward pricing give you confidence in both the service and the cost.

Technology That Delivers Results

Hydraquip’s Job Manager system provides real-time updates, full job traceability, and streamlined reporting. This technology improves efficiency and gives operators complete visibility of their repairs.

Conclusion

For waste management and recycling businesses in Northern Ireland, downtime is more than an inconvenience, it directly impacts contracts, costs, and customer satisfaction. Hydraulic hose reliability is central to keeping fleets on the road and plants in operation. That’s why having a trusted repair partner is essential.

Hydraquip provides the sector with 24/7 mobile hose repair, skilled engineers, and a first-time fix approach that reduces downtime and protects productivity. With proven expertise in waste and recycling, full coverage across Northern Ireland, and technology that keeps every job transparent and traceable, Hydraquip delivers more than just repairs – we deliver confidence that your operation won’t stop when a hose fails. Get in touch with the expert team today to learn more.